Applications

Packaging films and bags

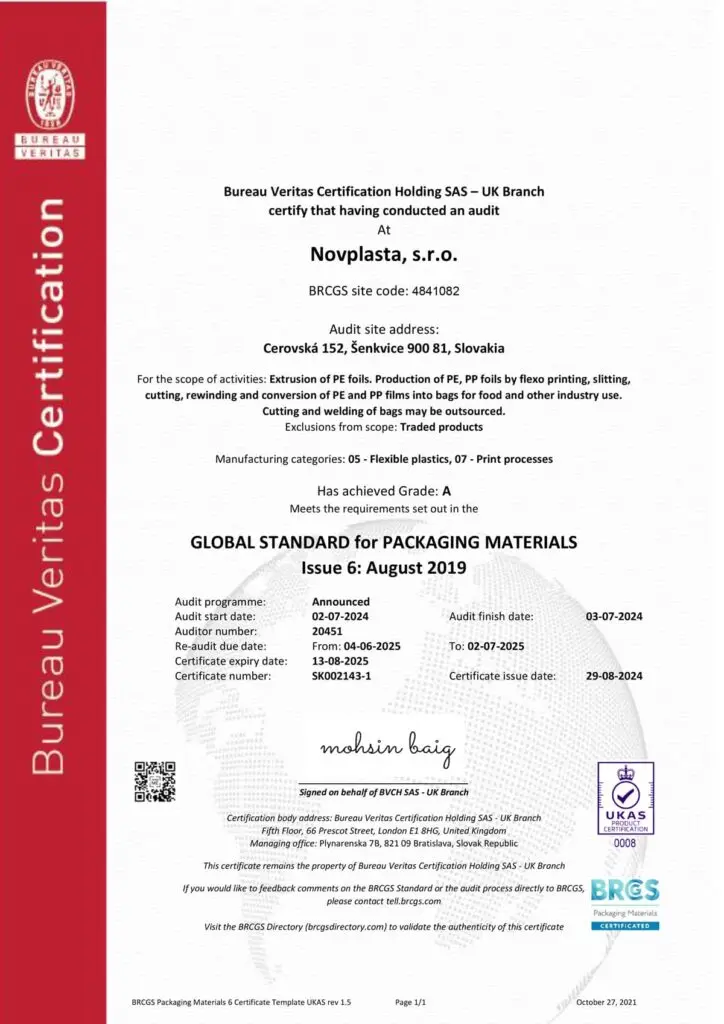

Food packaging

LDPE and HDPE films, bags, inliners and sheets are used in the food processing industry, especially for packaging of frozen vegetables, pastry, meat and fish and for protection during the manipulation with food products. They are used also in hotels, restaurants and catering. Our products are made from primary materials certified for direct contact with food. We maintain the standards of ISO 9001:2015, HACCP, good manufacturing practice and production traceability. The products are fully recyclable and suitable for energy recovery.

Industrial packaging

For industrial packaging, mostly LDPE and HDPE films, bags, inliners and sheets are used. Their main purpose is to keep the product intact and protect it from damage. They are used in various industries such as automotive, construction and agriculture (gravel, seed, animal feed), wood processing (wood pellets for heating), chemistry and plastics, and laundry services. Further uses include palletization packaging and shrink wrapping for group-packed goods. Protecting steel products from corrosion is a special application for our anti-corrosion VCI films made under the brand name Novacorr.

Pharmaceutical packaging

Our LDPE and HDPE films, bags and inliners are used for packaging of pharmaceutical chemicals and medical tools and drugs. We make them from primary materials certified for use in the pharmaceutical industry. The quality of our products was validated also by customer audits. We maintain the standards of ISO 9001:2015, HACCP, good manufacturing practice and production traceability. The products are fully recyclable and suitable for energy recovery.

Waste bags

Production areas

Production areas are (among others) manufacturing and assembly halls, kitchens, shops and warehouses. In production areas the labor effectivity is what really matters: the waste must be disposed quickly and safely. Here the quality of waste bags is much more important than in households. The strength and load capacity requirements are especially high. Our bags are made from a primary material rather than a regranulate, which guarantees the stable and even quality.

Cleaning services

Cleaning service firms value our bags for low weight, easiness of tear-off, good strength, high load capacity and stable quality. The worker does not waste time during the manipulation so that she can concentrate on the work. The bags are made from a first-class material – typically HDPE.

Waste separation

Bags for separated waste collection are used for example in municipalities, businesses, construction, health care, and asbestos disposal. Our waste separation bags are made of high-quality, strong, fully recyclable, nontoxic HDPE, LDPE or biodegradable material. The bags are made in various colors according to the type of waste, with optional printing.