Výroba

Extrúzia - potlač - konfekcia

Novplasta disponuje troma základnými technológiami na výrobu a spracovanie polyetylénových fólií – extrúziou, potlačou a konfekciou, čo umožňuje mať pod kontrolou celý výrobný proces. Tridsaťročné skúsenosti s vývojom receptúr, s výrobnými technológiami a úzke vzťahy s dodávateľmi sú zárukou spoľahlivosti a kvality.

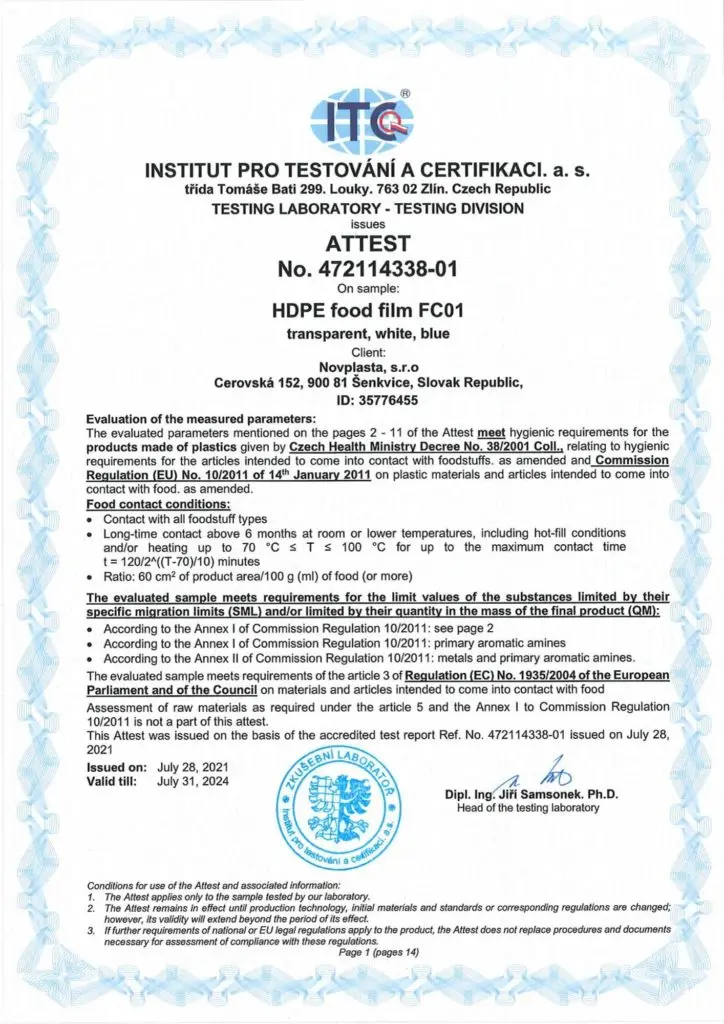

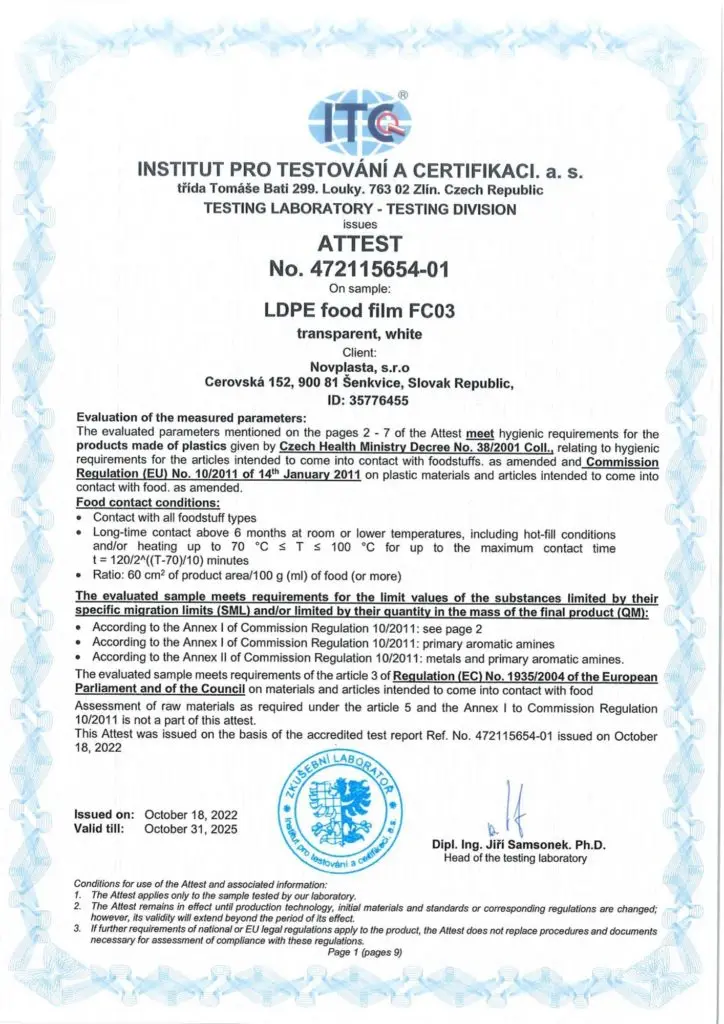

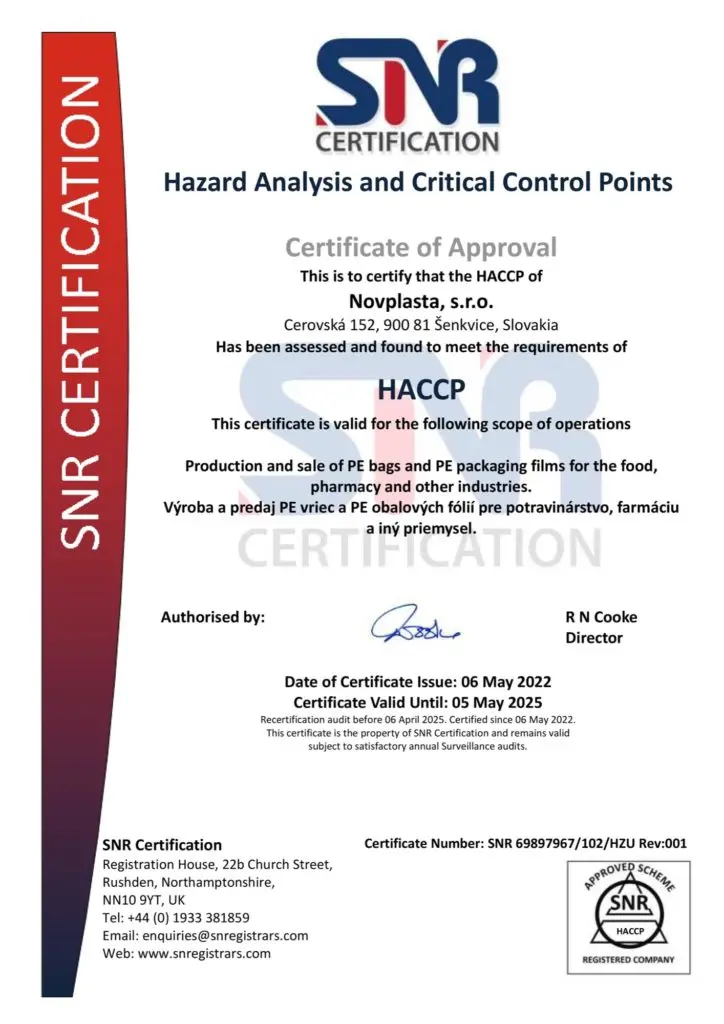

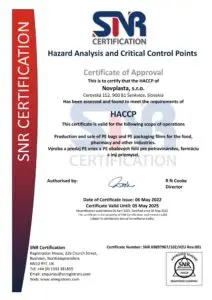

Firma má vytvorený a implementovaný systém manažérstva kvality podľa požiadaviek medzinárodnej normy ISO 9001:2015 a je držiteľom nasledovných certifikátov: